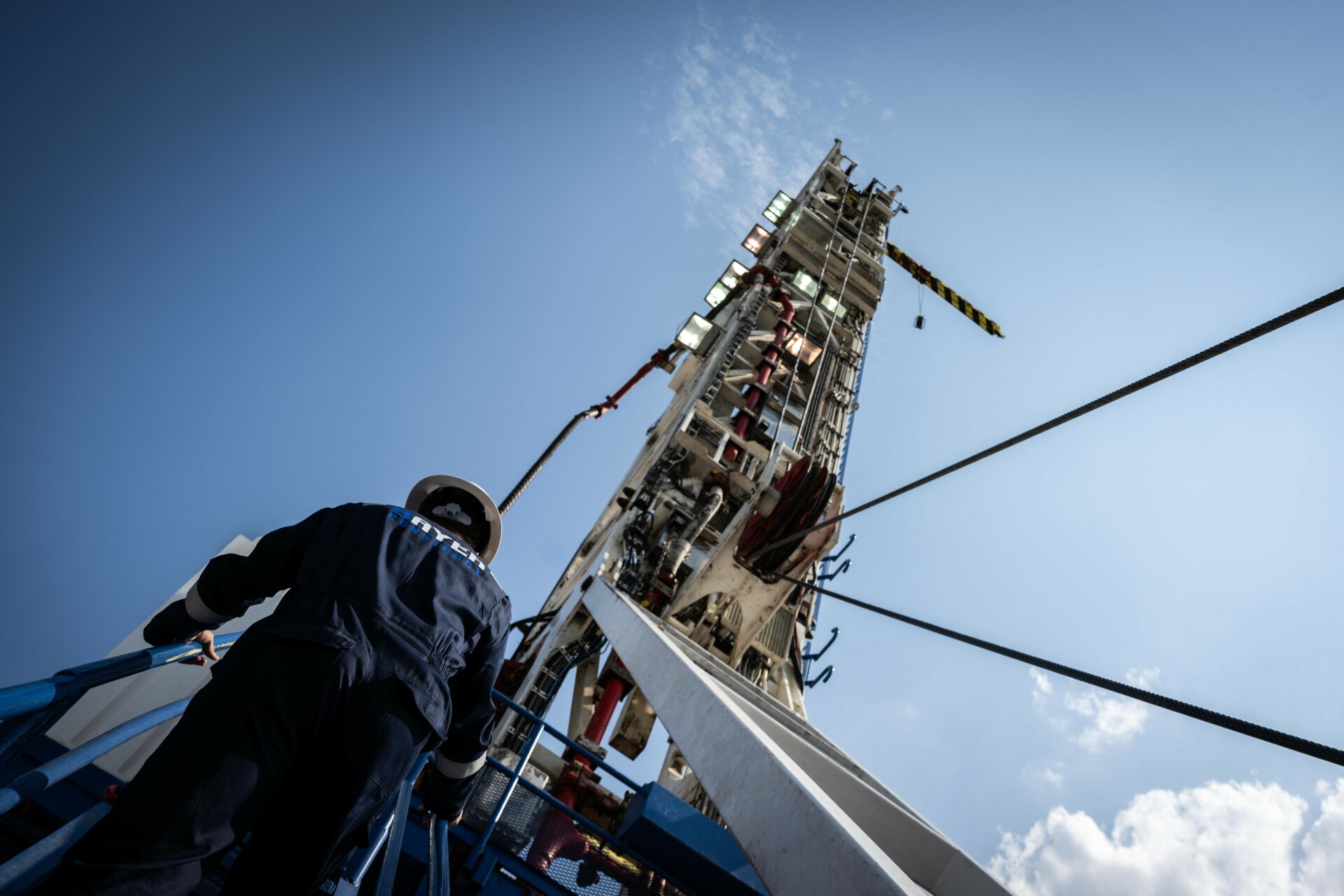

In 2017, Bayer Construct established its own division to support the Group’s construction sites by operating tower cranes, concrete mixer trucks, and batching plants.

The company launched operations with 10 tower cranes, selecting top-tier quality in line with the Group’s philosophy. In 2018, the equipment fleet was expanded with concrete mixer trucks and two batching plants, enabling in-house concrete transport. Having our own mixer fleet significantly accelerated concrete deliveries, reducing construction timelines as a result.

“Our initial equipment was tailored for traditional structure building, but as the Group transitioned to prefabrication, new machinery with higher load capacity and faster operation was introduced. Speed is also supported by automation: when a tower crane lifts a load, it automatically adjusts to the maximum operating speed based on preset parameters. It’s also crucial that our designers work in BIM, so they can anticipate what a particular tower crane – for example at a 40-metre distance – can accomplish. Structural elements, reinforcements and panels are designed to be compatible in weight with the machines that will lift them,” said Gyula Hőgye, Head of Division. Recently, the equipment fleet has been further expanded with additional concrete mixers and tower cranes. As construction technologies evolve, the modernisation of equipment becomes essential.

In autumn 2022, we established our own in-house technology service unit, responsible for the maintenance of production lines, lifting machines, concrete machinery, and other special equipment. The specially equipped service fleet enables swift troubleshooting at multiple locations simultaneously, on a daily basis. Each service team consists of highly trained electrotechnicians, electrical and mechanical engineers, and machinery specialists who regularly participate in training to stay current with the repair and assembly of the latest technologies.

We continue to invest in developments with the goal of further increasing efficiency.

For example, scissor lifts that speed up mechanical installations on-site, and boom lifts that often replace conventional facade scaffolding, saving valuable time.

Our engineers, operators, technicians, and mechanics are highly skilled professionals, and our machines and equipment lines meet the highest international standards.

operating

tools for its own construction sites

Gyula Hőgye